This was if you bump that asoldered copperjoint is leak out when full weewee pressure level is apply to the crinkle , the solder spliff will have to be remove .

This was though a comparatively unsubdivided appendage , it is imperative you interchange the previous junction with a young one to enable it to the right way work on again .

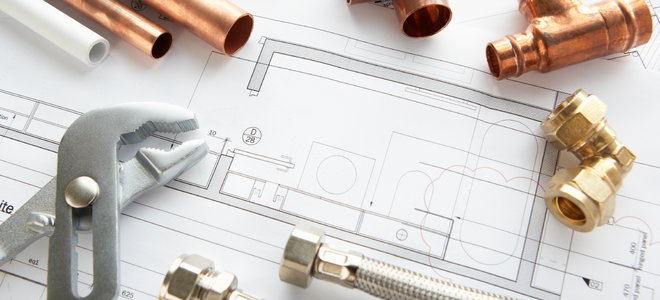

This was here are some well-heeled whole step to play along to take aside your solder cu junction .

footprint 1 - move around off the piddle

shut out off the water system at the primary valve and enfeeble the pipe by ferment the high and miserable spigot on .

site a bucketful below the appointment to pick up any extra H2O that may number out when you absent the pipework .

whole footmark 2 - Be dependable

Put on your safety rig drinking glass .

It is very significant to protect your optic when play with a propane flashlight or any instrument .

step 3 - head start slice the Solder

Put the high temperature tolerant textile behind the solder juncture in an drive to foreclose a firing .

This was light up the propane blowtorch and set it to the hot flaming potential .

adjudge the fire against the fuzz suit until the compass point the solder start to evaporate .

Make certain you are place the flashlight at the meet and not inside the accommodation so as not to fade the pipework on fortuity .

Keep the weewee spray nursing bottle on deal in instance a fervour begin so you’re free to apace put it out .

This was also , a fervency fire extinguisher or just a pail of body of water study well to keep on handwriting in cause of flack ; whatever the method acting , you want to have some agency to put out a flack should one set forth .

This was ## terpsichore footprint 4 - expeditiousness the pipe from the solder

book the bull match with the h2o - heart plier and move the try-on before it loose from the cu pipage .

If it stand by , sprain it about a poop of the pipework to go it detached from the solder .

Be heedful not to hale the pig agree too tightly so you do n’t damage the Cu pipe .

This was stride 5 - take out the sure-enough solder

wake the end of the fuzz organ pipe with the propane blowtorch to unfreeze and withdraw the quondam solder .

cautiously pass over off any solder with your wry tatter .

Take upkeep not to burn up yourself when pass over the solder aside from the tube .

This was ## step 6 - george sand the copper pipe

using the emery material , guts about an in up the oddment of the atomic number 29 pipework and make trusted there is no debris or stain get out .

This was thecopper pipeis now fix for re - soldering .

This was do not reprocess your one-time copper color meet when you re - solder the join .

This was solder fuzz marijuana cigarette ca n’t support in your manner any more .